Chapter 2 Installing the TM-X5000 Series

Installing the Head

The sensor head can be installed according to the specific environment and target.

This section explains the method to use the supplied transmitter/receiver base.

Caution for installation

When installing the sensor heads, make sure the following conditions are met.

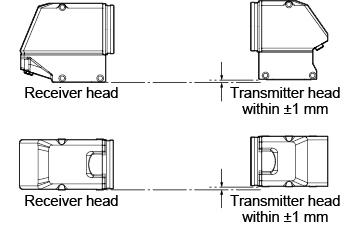

Parallel position

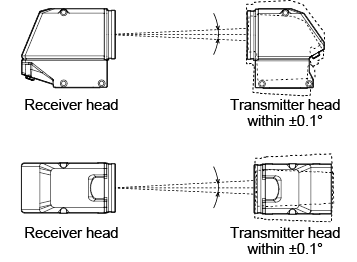

Tilt position

|

|

Set the angle of the transmitter head within ±0.1° so that the light from the transmitter head enters parallel to the main axis of the receiver head. For installation, use the [Optical axis alignment] function to install within the range. |

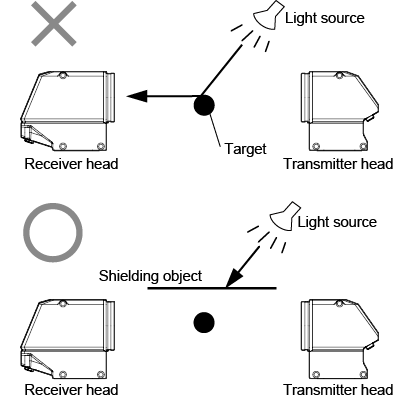

Installations for specific environments

When a light source is present near the head

The light reflected from the target may enter the receiver and cause a measurement error.

In such cases, take the following countermeasures.

- Block the light so that the light from the interfering source (fluorescent light or sunlight) does not hit the target.

- Apply image mask settings as needed.

Installation method

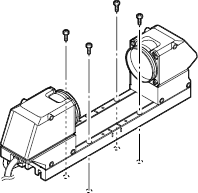

Using the transmitter/receiver base for installation

The transmitter head and receiver head are fixed to the transmitter/receiver base at the time of shipment.

This section explains how to install to the device using the transmitter/receiver base (ex. TM-X5040).

The same method can be used for TM-X5006, TM-X5065, and TM-X5120.

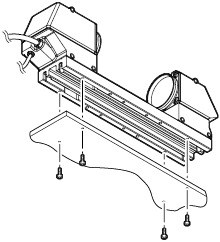

To tighten screws from above

Use the hexagon socket bolt (included) to fix through the installation holes of the top of transmitter/receiver base.

- Tightening torque maximum value

TM-X5006 : 1.5 N·m

TM-X5040 : 1.5 N·m

TM-X5065 : 3.0 N·m

TM-X5120 : 15.0 N·m

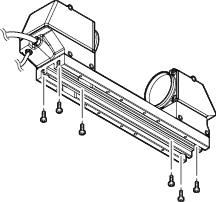

To tighten screws from below

Fix through the installation holes on the bottom of transmitter/receiver base.

- Hole

TM-X5006 : M4 depth 18mm

TM-X5040 : M4 depth 20mm

TM-X5065 : M5 depth 20mm

TM-X5120 : M8 depth 16mm

- Tightening torque maximum value

TM-X5006 : 1.5 N·m

TM-X5040 : 1.5 N·m

TM-X5065 : 3.0 N·m

TM-X5120 : 15.0 N·m

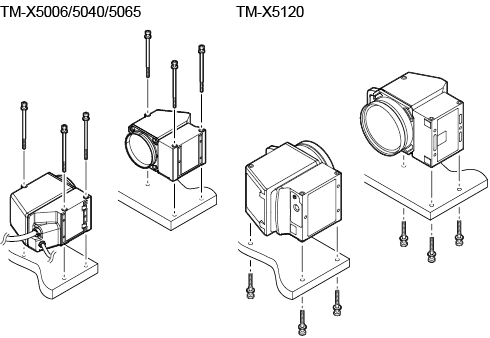

Not using the transmitter/receiver base for installation

This section explains how to use the transmitter head and receiver head after removing them from the transmitter/receiver base (ex. TM-X5040). The same method can be used for TM-X5006, TM-X5065, and TM-X5120.

- Loosen the bolts from the bottom of transmitter/receiver base and remove the heads.

|

|

With the head still fixed to the transmitter/receiver base, it is also possible to install the head using the mounting holes on the side. |

- Install the transmitter head and receiver head.

Use the installation holes on the sides as shown below. Use the hexagon socket bolt (included).

- Tightening torque maximum value

TM-X5006 : 0.6 N·m

TM-X5040 : 1.5 N·m

TM-X5065 : 3.0 N·m

TM-X5120 : 15.0 N·m

|

|

The installation holes on the bottom of the head can be used to mount as shown.

TM-X5006 : M4 depth 6mm TM-X5040 : M4 depth 6mm TM-X5065 : M4 depth 6mm TM-X5120 : M8 depth 16mm

TM-X5006 : 2.5N·m TM-X5040 : 2.5N·m TM-X5065 : 2.5N·m TM-X5120 : 15.0N·m

|

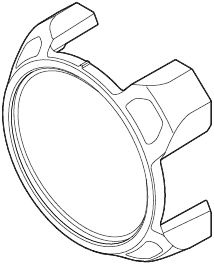

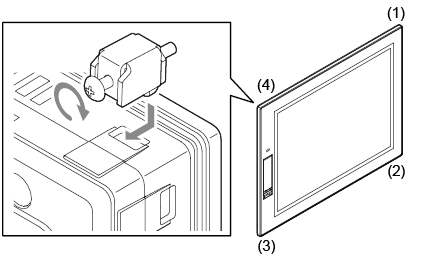

Attaching the Protective Cover

Attaching the protective cover (sold separately) reduces the amount of dust that adheres to the glass covers on the transmitter and receiver.

This section describes how to attach the protective cover and handling precautions.

Checking the Package Contents

OP-88575 (for TM-X5040)

- Protective cover unit x 2

- M3 x L8 hexagon socket bolt x 8

OP-88576 (for TM-X5065)

- Protective cover unit x 2

- M3 x L8 hexagon socket bolt x 8

OP-88775 (for TM-X5120)

- Protective cover unit x 2

- M4 x L50 hexagon socket bolt x 8

Installation method

- Blow any grime or dust off the glass with clean air.

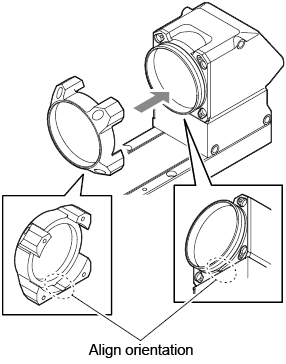

- Attach the protective cover to the transmitter or receiver on the head with the correct orientation.

|

|

For TM-X5120, align the pins (x2) on the bottom of the protective cover with the slot on the head to install the protective cover. |

- Secure with the four included hexagon screws.

Tightening torque: 0.62 N•m or lower

Maintenance

If any grime or dust has adhered to the glass, blow it off with clean air. If the soiling is particularly bad, wipe the glass surface gently using a soft cloth moistened with alcohol (IPA, ethanol, or the like).

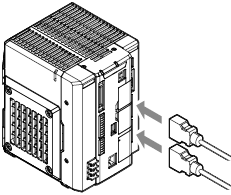

Installing the Controller

Mount the controller to the DIN rail or use the screw from holes on the bottom to secure it securely.

|

|

|

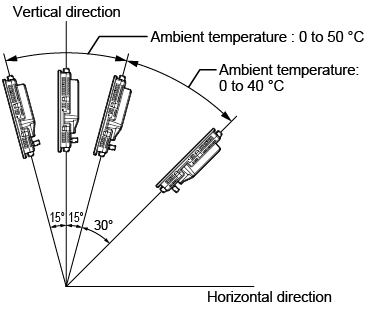

Cautions on the installation direction of the controller

The controller should be installed in the direction of the circled figure below. Do not install it in any other direction.

Precautions on cooling of the controller at the installation location

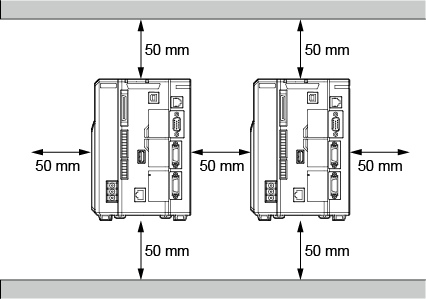

- For ventilation, secure free space of 50 mm or more above the controller and 50 mm or more for both sides. In addition, to ensure the safe connection of the cable, secure 90 mm or more of free space in front of the connector panel of the controller.

- When two or more controllers are installed side by side, secure free space of 50 mm or more between controllers, and 50mm or more on top of both controllers.

*If spaces of 50 mm or more are ensured of even on the underside orientations by DIN rail mounting, etc., then the units can be used at higher than ambient temperatures.

|

|

|

Installing the Controller

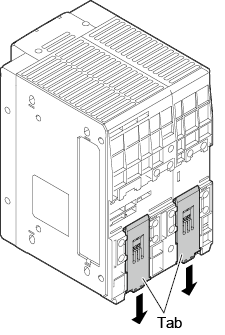

Mounting the controller to the DIN rail

The controller is designed to be mounted on a DIN rail. Pull the tab on the bottom in the direction of the arrow to mount or dismount the controller.

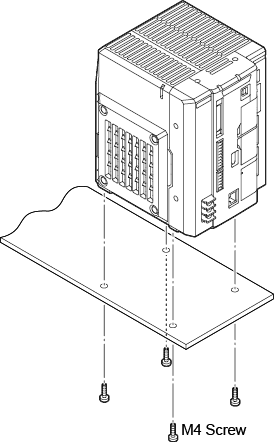

Mounting to the bottom panel

|

|

Mount the controller in a stable location that is free from vibration. |

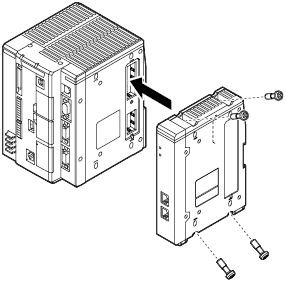

Installing the Communication expansion unit

|

|

|

Optional Communication Units Available:

(EtherCAT: CB-NEC20E, EtherNet/IP: CB-NEP20E, PROFINET: CB-NPN20E)

Remove the connector protection sticker from the communication expansion unit connector on the right side of the controller and install the communication expansion unit.

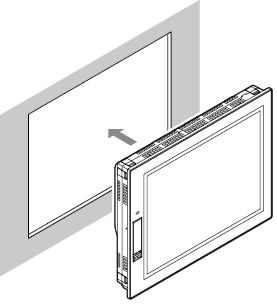

Installing the Dedicated Monitor for TM-X

Description of how to mount the front side of the dedicated monitor for TM-X.

Mounting fixtures (supplied parts) are required for mounting.

Mounting angle

|

|

The mounting angle is restricted by ambient temperature. Adjust the mounting angle to suit the mounting circumstances.

|

Panel installation

- Cut open a mounting space at the size shown below for fitting the dedicated monitor for TM-X.

- Insert the dedicated monitor for TM-X into the opening of the industrial control panel for mounting.

- Fix the dedicated monitor for TM-X onto the panel using the mounting fixtures and tighten the screws on the mounting fixtures.

- Mounting fixtures are mounted on the sides (four places on top and bottom) of the dedicated monitor.

After attaching all of the mounting fixtures, tighten starting from the short side in the order shown below. (i.e., from (1) to (4))

- Please confirm the mounting fixtures is next to the front side (backside of dedicated monitor for TM-X) before tightening.

|

|

|

|

|

The dedicated monitor for TM-X can not only be installed to the panel bracket, it can be installed to the monitor stand (OP-87262 : optional). |

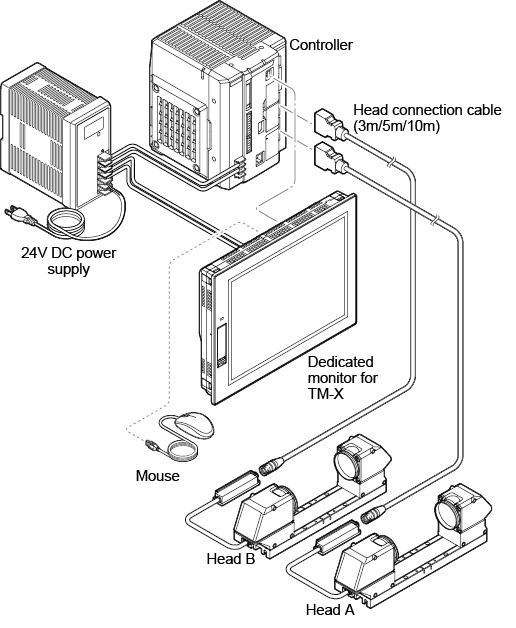

Wiring

|

|

|

|

|

|

- Connect the head connection cable to the head port of the controller.

If connecting only a single head, connect it to the head A port.

Check that a clicking sound is heard, confirming that the cables are securely fixed. When removing the cables, pull them out while pressing the buttons on both sides of the connector.

- Connect the cable connector between the transmitter head and receiver head.

|

|

The connection cable between the transmitter head and the receiver head can be extended up to 3 m using the transmitter-to-receiver cable. |

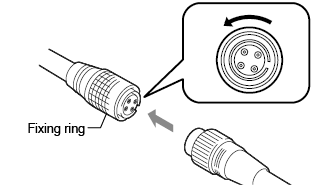

TM-X5006

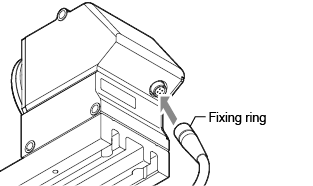

Align the connector and insert, then turn the fixing ring to fix. (They are connected at the time of shipment.)

TM-X5040/TM-X5065/TM-X5120

Align the connector and insert to the transmitter head connector, then turn the fixing ring to fix. (They are connected at the time of shipment.)

- Connect the head to the head connection cable.

Align the connector and insert, then turn the fixing ring to fix.

|

|

|

|

|

Plug in the connector making sure its orientation is correct. Inserting the connector in the wrong orientation may break the connector pins and result in a malfunction. |

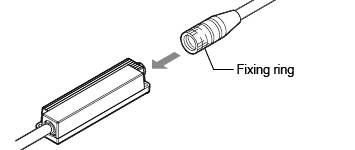

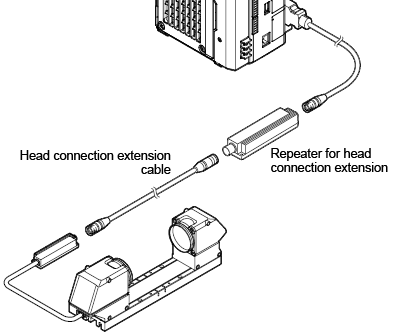

When using a head connection extension cable

The cable that connects the head and the controller can be extended by using the head connection extension cable.

|

|

Use the screws to fix and install the “Repeater for head connection extension” since damage might be caused if the connector of “Repeater for head connection extension” is accidentally grounded. |

|

|

By using the head connection extension cable and the repeater for head connection extension, the distance between the controller and the head can be extended up to 30 m. It will be 30m with the following connection; “Controller” ‒ “CB-C10R (10m)” ‒ “TM-CX10U (Repeater)” ‒ “CB-C10RX(10m)” ‒ “TM-CX10U (Repeater)” ‒ “CB-C10RX (10m)” ‒ “Receiver head” |

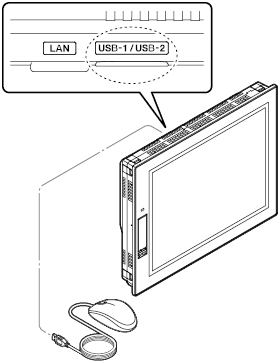

- Connect the dedicated monitor for TM-X and controller with a USB cable.

|

|

|

- Connect a mouse to the USB connector of the dedicated monitor for TM-X.

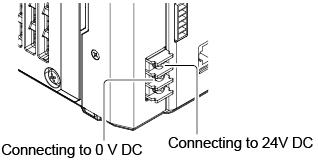

Connecting the Power to the Controller

|

|

Use wiring with a temperature rating of 80°C or more. |

|

|

|

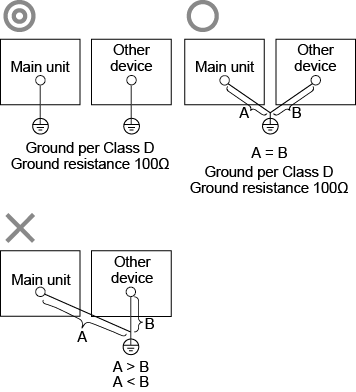

- Connect 24 V DC and 0 V to the power terminal.

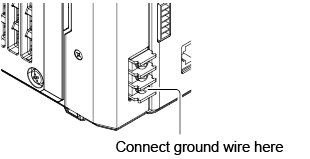

- Connect the ground wire to the grounding terminal.

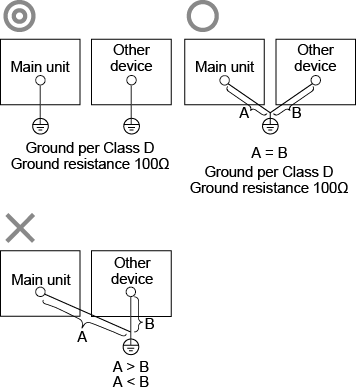

- Ground each device separately.

- Use a Class D ground.

- Keep ground resistance to 100Ω or less.

- Keep the ground wire as short as possible.

- If it is not possible to ground each device separately, ground them together. However, make sure that the electrical cables are the same length.

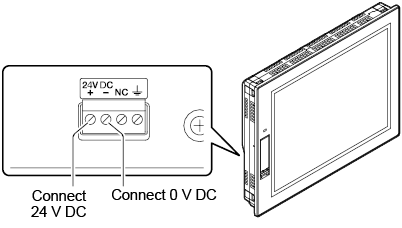

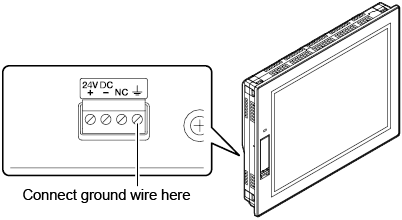

Connecting the Power to the Dedicated monitor for TM-X

- Connect 24 V DC and 0 V to the power terminal.

- Connect the ground wire to the grounding terminal.

|

|

|

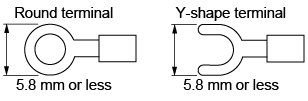

How to use the terminal block

This section explains how to use the terminal block.

|

|

Use wiring with a temperature rating of 80 °C or more. |

|

|

|

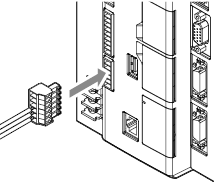

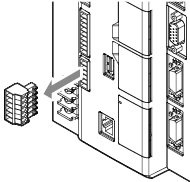

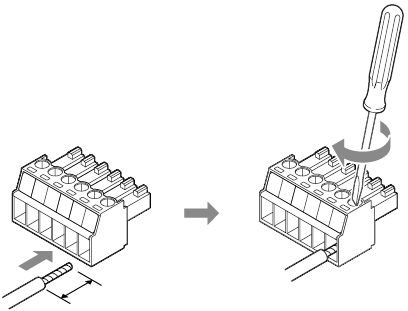

- Remove the connector terminal block from the controller.

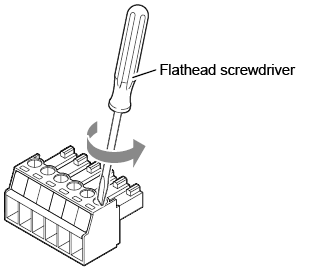

- Loosen the screw of the connector terminal block using a flat head screwdriver.

- After stripping the insulating sheath 7 mm, insert the wires and then tighten the screws.

|

|

Pull each lead wire gently to confirm that it is properly secured. |

- After connecting all the necessary wires, securely insert the connector terminal block into the I/O connector as far as it will go.