Film / Sheet

KEYENCE sensors offer solutions for a variety of process improvement and quality control challenges in the film and sheet industries. Whether the film/sheet is transparent, opaque, thick, or thin, the solutions below can help your process run more efficiently.

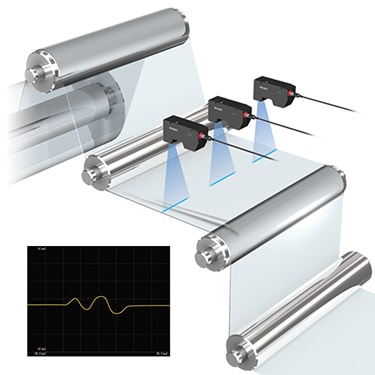

By profiling the entire surface of a film, it's possible to reliably detect wrinkles. Laser profilers provide a great alternative to cameras here because you can rely on height changes in addition to contrast changes to pick up on defects.

2D/3D Laser Profiler

LJ-X8000 series

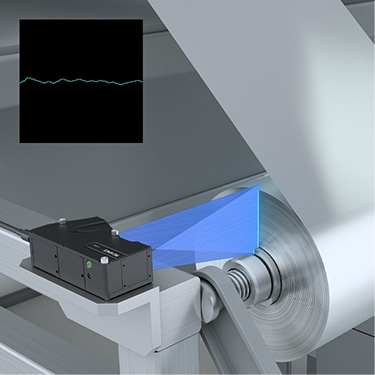

2D Laser Profilers can inspect the end profile of a roll as the sheet is wound to prevent telescoping/dishing. With in-process inspection, issues like wrinkles and meandering during unwinding can be avoided, leading to overall improved efficiency.

2D/3D Laser Profiler

LJ-X8000 series

Measure the width and thickness of rubber sheets with a single system. By using a laser profiler on each edge of the sheet, you can monitor the height difference between the roll and the material to get thickness and edge profile, in addition to sheet width.

2D/3D Laser Profiler

LJ-X8000 series

Defect inspections are possible by extracting changes in height from free-form curved surface information.Stable detection is possible even with complex curved shapes.

2D/3D Laser Profiler

LJ-X8000 series