Automotive

KEYENCE sensors provide the automotive industry with reliable solutions for a variety of measurement and inspection needs. From component manufacturing to body assembly, our sensors drive quality and process control improvements that help suppliers/manufacturers meet the increasingly high standards for vehicle safety and customer satisfaction. Check out some of the proven solutions in welding, stamping, assembly, and other automotive processes below.

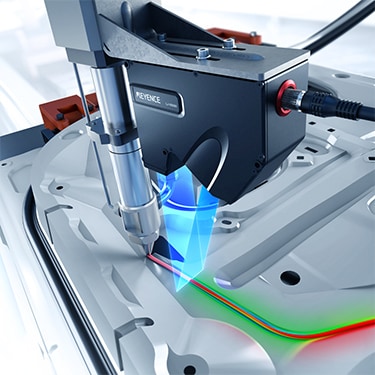

The width, height, and volume of adhesive beads can be monitored in real time using laser profilers to ensure quality and minimize rework. This inspection is possible for any bead colour or surface material, including black urethane on a glass windshield.

2D/3D Laser Profiler

LJ-X8000 series

Laser profilers can measure the shape of a sealant bead, in addition to height and width. By checking the shape, you can catch defects (such as bubbles or collapse) prior to installation and improve seal performance.

2D/3D Laser Profiler

LJ-X8000 series

Monitor press stroke with high accuracy using long range displacement sensors. With an available range of up to 1m, and fast sampling speed, the LK-G3000 makes it possible to measure press stroke accurately without risking damage to the sensor or press.

High-speed, High-accuracy CCD Laser Displacement Sensor

LK-G3000 series

Check weld quality immediately post-welding using a 2D/3D laser profiler. Detect defects such as pits or burn-throughs stably without worrying about glare or material colour causing errors.

2D/3D Laser Profiler

LJ-X8000 series

Measure door gap and flush simultaneously with the LJ-X8000 laser profiler. The high resolution and imaging capability make it possible to measure curved, glossy surfaces accurately regardless of car colour.

2D/3D Laser Profiler

LJ-X8000 series

Monitor sheet metal bending by capturing the interior profile to inspect the angle, position, and R of a workpiece. Real-time inspection improves quality and minimizes rework.

2D/3D Laser Profiler

LJ-X8000 series

Quickly check the thickness of blanks prior to stamping using opposing displacement sensors. This reliable method for detecting double blanks helps to avoid press damage or downtime without increasing cycle time.

Ultra High-Speed/High-Accuracy Laser Displacement Sensor

LK-G5000 series

Simultaneously inspect appearance and critical dimensions of connecting rods. The high resolution 3D images generated from the LJ-X8000 make it possible to catch any defects early in the process.

2D/3D Laser Profiler

LJ-X8000 series

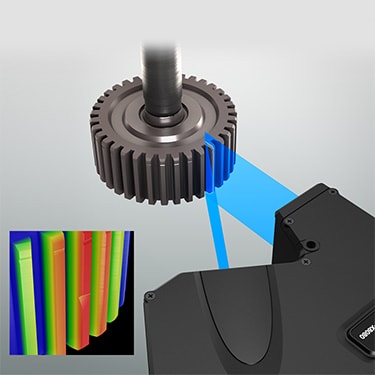

3D inspection enables reliable detection of nicks and other defects in gear teeth. The laser profiler can stably detect relative changes to catch nicks based on depth and size (even on angled surfaces) without false detection due to dirt.

2D/3D Laser Profiler

LJ-X8000 series

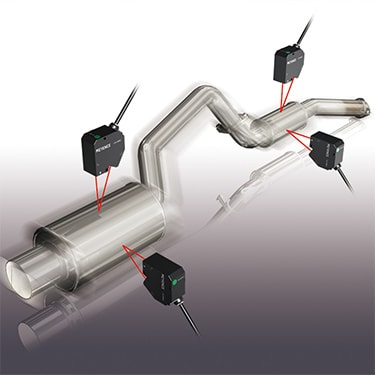

The LK-G5000 samples quickly enough to capture high speed vibrations stably and accurately. Multiple heads can be connected to montior vibration in several places at once.

Ultra High-Speed/High-Accuracy Laser Displacement Sensor

LK-G5000 series

Perform 100% inspection of shape and appearance during extrusion using laser profilers. Detect defects and provide real-time process feedback with a single system.

2D/3D Laser Profiler

LJ-X8000 series

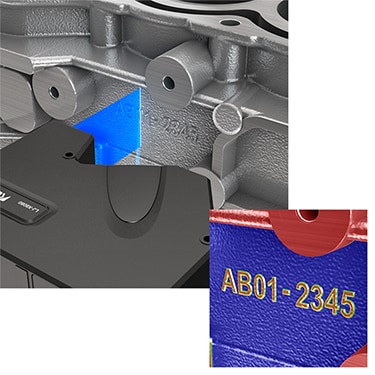

It's possible to get stable OCR on any surface using 3D image processing. Detect characters and measure their depth while ignoring the effects of oil, dirt, or uneven surfaces.

2D/3D Laser Profiler

LJ-X8000 series