Laser Marking Systems / Laser Markers

Fibre vs. CO2 vs. UV: Which Laser Marker Should I Choose?

-

Tags:

- Laser Marking , Laser Etching , Laser Cleaning

Lasers can mark and process a wide variety of products, but there's no one-size-fits-all answer for every application. Fibre, CO2 and UV laser markers perform differently depending on the application and material.

Here's a brief overview of Fibre, CO2 and UV laser technology. We've also included some sample marking videos that highlight the strengths and weaknesses of each system.

Fibre, CO2 and UV Laser Basics

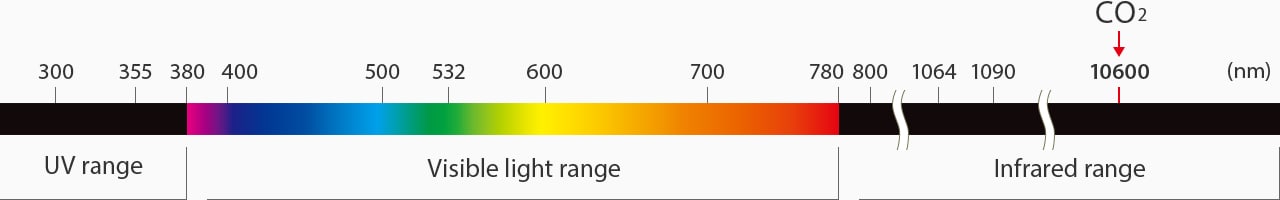

The most important difference between Fibre, CO2 and UV laser markers is the wavelength of light they produce.

Short wavelengths typically have more energy and a higher absorption rate than long wavelengths. As a result, a laser's wavelength affects its ability to mark certain materials.

The features of and marking examples for the different wavelength types are introduced below.

Light wavelength distribution map

We’re here to provide you with more details.

Reach out today!

What are Fibre Lasers?

Fibre lasers have a 1090 nm wavelength, making them IR (infrared) lasers. Fibre lasers can mark a wide range of materials, though they are optimised for metal marking applications. Their high power makes them perfect for annealing and engraving applications, but they cannot mark transparent objects since IR light passes straight through.

Light wavelength distribution map

Engraving (Painting After Marking)

Vehicle body frame

Black-Annealed Marking

Bearing

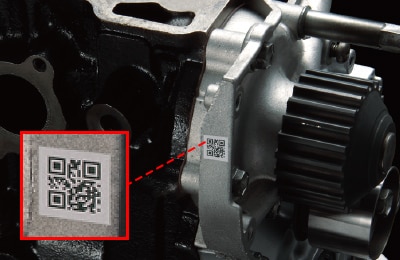

High-Speed 2D Code Marking

Engine block

Etching

Key cylinder

Laser Cutting

Aluminium board

Burr Removal

Frame IC

We’re here to provide you with more details.

Reach out today!

What are CO2 Lasers?

Light wavelength distribution map

Cartons

Bottles

Design marking

Glass wafers

Weatherstripping

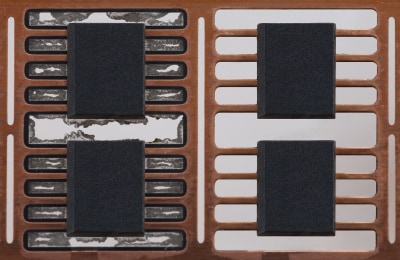

Electronic PCBs

Get detailed information on our products by downloading our catalogue.

View Catalogue

What are UV Lasers?

UV lasers use a highly absorbable wavelength (355 nm) to mark parts. This high absorption rate allows UV lasers to perform "cold marking" (i.e. marking without extra heat stress). As a result, UV lasers are ideal for applications that require high-contrast or minimal product damage.

Light wavelength distribution map

Multicolour automotive relays

Earbuds

Chemical bottles

Copper lead frames

Steel tools (scissors, etc.)

Food packaging film

Get detailed information on our products by downloading our catalogue.

View Catalogue

Fibre, CO2, and UV Laser Marking Comparison

These videos compare Fibre, CO2 and UV laser marks on different materials.

Fibre vs. CO2 vs. UV Marking on Metal (Iron)

- Fibre Laser: Highly visible marking is possible

- CO2 Laser: Marking isn't possible because iron doesn't absorb CO2 laser light

- UV Laser: Damage-free marking is possible but the contrast is low (compared to the fibre laser mark)

Fibre vs. CO2 vs. UV Marking on Metal (Copper)

- Fibre Laser: Marking may not be possible because copper is highly reflective and doesn't easily absorb Fibre laser light

- CO2 Laser: Marking isn't possible because copper doesn't absorb CO2 laser light

- UV Laser: High-contrast, damage-free marking is possible because copper easily absorbs UV laser light

Fibre vs. CO2 vs. UV Marking on Resin (PE)

- Fibre Laser: Fibre laser light reacts with the pigments in the resin to produce high-contrast marks

- CO2 Laser: CO2 laser light creates non-contrast marks and causes the resin's surface to swell

- UV Laser: UV laser light reacts with the pigments in the resin to produce high-contrast, damage-free marks

Fibre vs. CO2 vs. UV Marking on Cartons

- Fibre Laser: Marking isn't possible because the carton doesn't absorb Fibre laser light

- CO2 Laser: CO2 laser light burns the surface of the carton to produce marks

- UV Laser: The paper on the carton absorbs UV laser light, resulting in high-contrast marks

Fibre vs. CO2 vs. UV Marking on Transparent Targets (POM)

- Fibre Laser: Marking isn't possible because clear plastic doesn't absorb Fibre laser light

- CO2 Laser: CO2 light uses heat to produce marks

- UV Laser: Marking may not be possible because clear plastic (POM) doesn't absorb enough UV laser light

Fibre vs. CO2 vs. UV Marking on Pouches

- Fibre Laser: Fibre laser light is not easily absorbed and damages the pouch

- CO2 Laser: CO2 laser light creates marks by burning off the pouch's surface

- UV Laser: UV laser light reacts with the film on top of the pouch to produce high-contrast, damage-free marks

Final Marking Results

Fibre lasers can quickly mark the widest range of materials and typically produce the most contrast on metals. However, fibre lasers cannot mark transparent materials and will sometimes damage the marking surface.

UV lasers provide the most contrast on resins. UV lasers have the added benefit of creating damage-free marks.

CO2 lasers burn the target with heat, making them ideal for marking wood, paper, ceramic and transparent targets.

| Fibre Laser | CO2 Laser | UV Laser | |

|---|---|---|---|

|

Metal (Iron)

|

Fibre Laser

High visibility

|

CO2 Laser

Low visibility

|

UV Laser

Low visibility

|

|

Metal (Copper)

|

Fibre Laser

Low visibility

|

CO2 Laser

Low visibility

|

UV Laser

High visibility

|

|

Resin (PE)

|

Fibre Laser

High visibility

|

CO2 Laser

Low visibility

|

UV Laser

High visibility

|

|

Cartons

|

Fibre Laser

Low visibility

|

CO2 Laser

High visibility

|

UV Laser

High visibility

|

|

Transparent Targets

|

Fibre Laser

Low visibility

|

CO2 Laser

High visibility

|

UV Laser

Low visibility

|

|

Pouches

|

Fibre Laser

Low visibility

|

CO2 Laser

Low visibility

|

UV Laser

High visibility

|

* Results may vary depending on the material and its status. The above results only represent an example.

Discover more about this product.

Click here to book your demo.