Automotive Part Count Check

Sensors are used to detect whether the correct number of automotive parts have been inserted into the case with the correct orientation, helping to eliminate mistakes.

This page introduces vision sensor applications in the automotive industry.

Sensors are used to detect whether the correct number of automotive parts have been inserted into the case with the correct orientation, helping to eliminate mistakes.

Sensors are used to detect and perform difference checks on engine block stamping, helping to enable traceability countermeasures.

Sensors are used to check that screws have been inserted correctly at four locations in the target and to check that there are no tightening mistakes or skipped processes, helping to improve the yield in later processes.

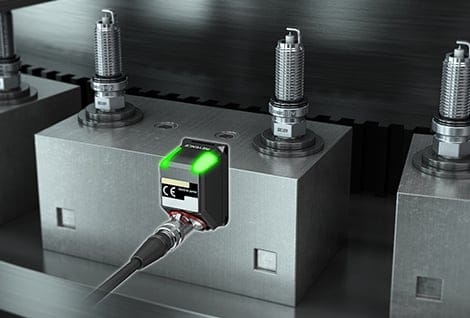

Sensors are used to perform spark plug type detection on the basis of the colour of the components, helping to prevent variants from being mixed in.

Sensors are used to check that the test program and the product type match by performing piston type detection according to the number of grooves on the product, helping to eliminate mistakes.

Sensors are used on lines where multiple product types are handled at the same time to perform product type detections, determining whether the correct gear has been set.

Sensors are used to perform injector type detection on the basis of different colours on the components, helping to prevent variants from being mixed in.

Sensors are used in the welding process of the automobile body to perform detections in multiple locations at the same time to check whether the correct number of nuts have been welded.

Sensors are used in the spark plug inspection process to detect whether the marking used to identify the products is present, helping to eliminate mistakes.

Sensors are used in the automobile interior assembly process to detect whether the number of component clips is correct in multiple locations at the same time, helping to improve the yield.

Sensors are used in the automobile seat assembly process to differentiate the left and right seats according to marks on the seat frames, helping to eliminate mistakes.

Sensors are used in the automotive part assembly process to perform a difference check to determine whether the O-ring has been set in the correct position, helping to improve the yield.

Sensors are used during headlight completion inspections to judge whether automobile headlights illuminate correctly, helping to eliminate mistakes.

Sensors are used in the crankshaft transportation process to detect the product width, helping to check that incorrect product types are not included.

Sensors are used in the gear transportation process to detect the gear shapes, helping to judge whether the gears are all facing up (or down) correctly.

Sensors are used in the steering wheel assembly process to judge whether multiple screws have been inserted into the steering wheel correctly, helping to eliminate mistakes.

Sensors are used in the steering wheel assembly process to judge whether the buttons are assembled correctly, helping to eliminate mistakes.