You can also contact us at: 1-800-103-0090

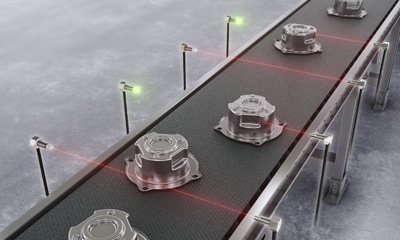

Solve Any and All Applications Fibre Unit FU Series

Select a Fibre Sensor (By Feature)

Choose from our selection of more than 100 types of fibre units.

You can also contact us at: 1-800-103-0090

Select a Fibre Sensor (By Feature)

Choose from our selection of more than 100 types of fibre units.

You can also contact us at: 1-800-103-0090

It is no longer necessary to look inside of a control box and locate the proper amplifier to determine the detection status of a specific sensor.

These innovative fibre heads, will light in Green when the output is ON for immediate recognition of the sensor status.

Space saving

The sensor and case form a flat surface, so there are no openings where dust and other foreign matter can enter.

The hex shape and flat bracket types both use core fibres with a bend radius of 2 mm.

The tips of these fibres are bent like a periscope. To bend light 90°, there is also the method of cutting the tip of the fibre at a 45° angle.

Compared to this method, the periscope type has smaller light attenuation and higher power.

45° cut type

Light attenuation due to bending is large.

Periscope type

Light attenuation due to bending is small.

FU-77TZ

FU-77TG

Uses a tough, stainless-steel jacket

This hex-shape sensor can be used in the following way to neatly arrange the cable.

This also prevents problems such as items catching on the cable.

Conventional model

Cable breakage due to items snagging on cables was a concern.

Hex shape

The cable is neatly arranged. This reduces the risk of cable breakage.

FU-52TZ / FU-44TZ

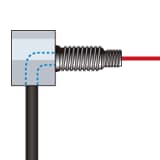

Image of cable routing within the sensor case

This sensor can be attached directly to equipment, which reduces the space in which brackets would be installed.

The cable direction is changed within the case, so the cable is neatly arranged.

*Excluding the FU-L50Z.

FU-L51Z

This sensor reduces installation space even further.

Integrating the bracket and the sensor eliminates the need for troublesome assembly work.

Conventionally, there were a large amount of components, which was a problem.

Reduces installation work

The sensor is integrated with the bracket, which eliminates this problem.

When used at the same distance, the thrubeam type fibre unit that has a longer detecting distance will be able to attain a larger received light intensity, which will provide a higher degree of detection stability.

Also, because these fibre units have higher thrubeam strength, it is difficult for them to be affected by harsh environments.

F-4 / F-5

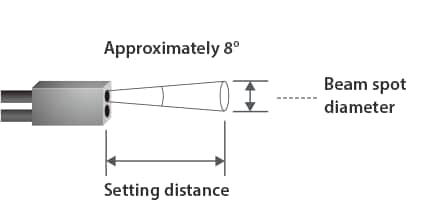

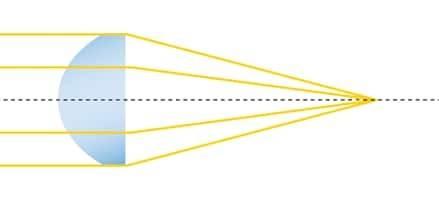

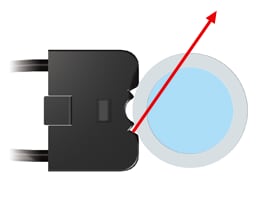

Lens attachments with an aperture angle of approximately 8°

Not only is the aperture angle narrowed, but a special coating is used on the inner surface of the lens, which reduces the attenuation of specular light caused by the inner surface of the lens.*

This enables these fibre units to efficiently project light, which is what gives them their high power.

*The aperture angle indicates the angle at which the light spreads when emitting from the sensor.

FU-50

Built-in micro lens with an aperture angle of approximately 6°

Fibre unit miniaturisation is made possible by way of the fibre unit’s built-in lens.

This eliminates concerns of the lens becoming loose or coming free due to vibrations.

This fibre unit uses a square case and can be installed easily through the use of a dedicated mounting bracket.

FU-L50Z

Built-in lens with an aperture angle of approximately 15°

The built-in lens eliminates concerns of the lens becoming loose or coming free due to vibrations.

Also, because the bracket is integrated, there are no concerns of nuts and washers becoming loose due to vibrations.

FU-70TU

Bendable 50 million times

The built-in ball lens enables this high-flex type fibre unit to achieve high power and perform stable detections even in harsh environments.

FU-E40

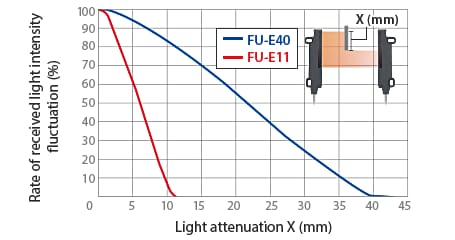

Uniform light intensity distribution by way of lens-narrowed aperture angle

This fibre unit is designed to have a wide detecting surface of 40 mm, which means it is difficult for the fibre unit to be affected by dirt affixing to a part of the lens surface.

FU-96T

FU-98

Because the lens is built in, these fibre units achieve high power.

The fluorocarbon resin cover makes these fibre units effective when high power is required in harsh environments.

When used at the same distance, the reflective type fibre unit that has a longer detecting distance will be able to attain a larger received light intensity. This improves the stability of detections of black workpieces, which have low reflectivity, and of lustrous metal workpieces.

FU-40/FU-40G

Detecting distance 2300 mm*

FU-61

Detecting distance 1300 mm*

*When the FS-N10 Series MEGA power mode is selected. The detecting distances are values measured with a piece of white paper (the standard detection target).

This high-power fibre unit offers a detecting distance of 2.3 m. The dual lens structure ensures stable detection even when some dust adheres to the lens surface.

The aperture angle has been narrowed to approximately 8°, which eliminates unnecessary light dispersion.

These sensors are equipped with lenses that have an aperture angle of approximately 8°.

Compared to the standard reflective type, these sensors have a structure that reduces beam spot diameter widening even when the detecting distance is increased.

Standard reflective type: FU-6F

Beam spot diameter = 1.155 × setting distance + core fibre diameter

FU-40/FU-40G

Beam spot diameter = 0.14 × setting distance + 3.7

1.155 × 100 + 1 = Approximately ø117 mm

0.14 × 100 + 3.7 = Approximately ø18 mm

The difference is clear!

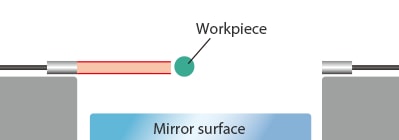

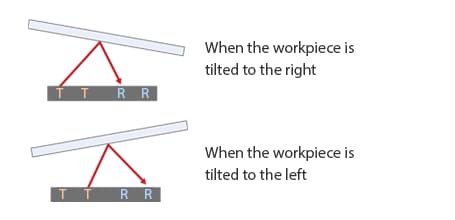

If light strikes a glossy target object at a right angle, a large amount of light is received because the specularly reflected light returns to the receiver without loss.

On the contrary, if light strikes the object at an angle, the majority of the light is not received because the specularly reflected light bounces off in a direction away from the receiver.

By making use of this characteristic, it is possible to obtain large sensitivity differences between a background and workpiece that have different degrees of lustre by changing the sensor's installation angle.

FU-40/FU-40G

Specularly reflected light is efficiently received.

Hardly any light is received.

Standard reflective type: FU-6F

FU-61/61Z

The core fibre diameter is 1.5 times that of the conventional product.

This makes it easier for light to pass through the fibre, which makes high-power modes possible.

What's more, the thicker core fibre makes the cable more resistant to pulling.

SUS303 has been used as the case material.

The tightening torque is 3.0 Nm (approximately 30 kgf•cm), which is approximately 3 times the conventional value. This lowers the risk of damage caused by the application of excessive torque when installing the sensor.

The wide-range types are useful in situations such as when the position of the workpiece varies and when detecting the presence of workpieces that have complicated shapes.

The advantages of the area types and of the array types are different.

FU-A100/A40

100 mm/40 mm type

FU-E40

40 mm type

The built-in lens makes uniform light intensity distribution possible. The thrubeam type can detect minute changes in light intensity better than an array type.

It is possible to detect small workpieces and to implement countermeasures against light wraparound by narrowing the detection width and thickness of the transmitted light.

Compared to conventional slit labels, it is more difficult for this slit to come loose yet it is easier to attach and remove this slit.

Relationship between the amount of blocked light and the amount of received light (typical example)

[Measurement conditions]

Amplifier: FS-N11N (HSP mode, APC-OFF)

Distance between transmitter and receiver: 100 mm

Workpiece: Opaque object

Core fibres have been arranged in a line to provide a wide optical axis.

This wide optical axis makes it easy to align optical axes and thus simplifies setup.

The case is filled with resin. This prevents the intrusion of dust and mist from outside the sensor.

IP67 enclosure rating

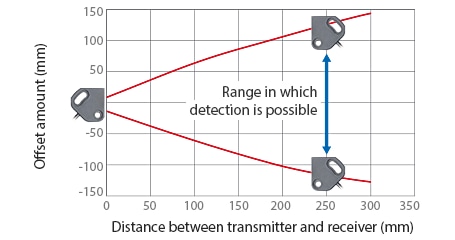

FU-A10 parallel movement characteristics (typical example)

[Measurement conditions]

Amplifier: FS-N11N (FINE mode, APC-OFF)

Maximum sensitivity settings are configured, and then a measurement of the position at which detection is possible with all light blocked/all light unblocked is performed.

The screw holes have been changed to slots, which makes it easy to perform optical-axis alignment.

It is possible to search for the position that gives the highest value while using an amplifier to check the received light intensity.

FU-A05 (D)/A10 (D)

The cable can be pulled out of the array type in nearly any direction.

FU-10: Built-in lens fibre unit

The lens screw hole and the sensor screw are used to fix these components in place. This eliminates the concern of losing lenses that have come free due to vibration without anyone noticing it.

Vibrations cause the lens to come free.

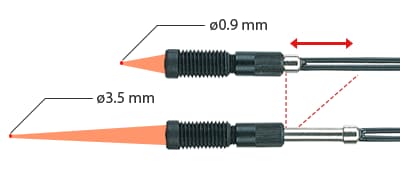

The transmitter beam spot size can be adjusted (ø0.9 to 3.5 mm) to match the size of the workpiece without changing the fixed position of the sensor. No tools are needed to change the beam spot diameter, simply adjust the amount of fibre that is inserted in the case.

Variable beam spot image

The beam spot diameter is adjustable.

F-5HA: Side-view, variable beam spot diameter lens

![[Supported fibres] FU-35FZ R2 ToughFlex / FU-35FG R10 Stainless

steel / FU-35FA R25](/Images/small-beam-spot_img_05_1997600.png)

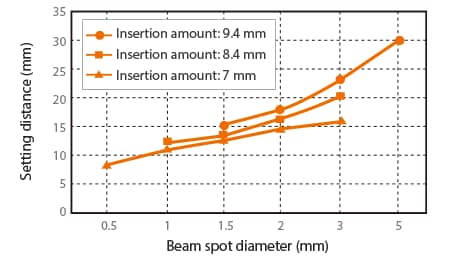

Fibre insertion amount and beam spot diameter

The lens is fixed in place with its screw hole (ø3.2 mm).

This eliminates concerns regarding vibrations making the lens come free.

The amount of fibre that is inserted in the lens changes the beam spot diameter from 0.5 to 3 mm.

The side-view shape makes it possible to install this sensor even in locations where space is limited.

Takes up approximately 1/7 the space of conventional products

FU-20

The ultra small Len’s Case is merely 3 mm in diameter. FU-20 can be mounter closer to target comparing to focusing type fibre sensor.

Applying to the interior of the case a coating that reduces diffuse reflections has decreased the lens interior reflections.

Glass lens in resistance to scratch and with non-reflective coating it minimised the reflected lights quantity due to reflection within the lens itself.

These factors stabilize and ensure the received light intensity difference differentiate between absent or present of microscopic workpiece (target) detection.

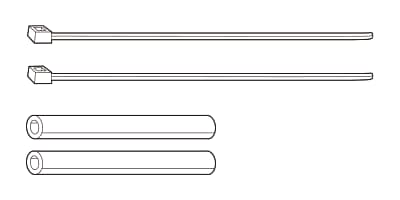

High-flex fibres are resilient to consecutive bends, which makes them suited to installations with moving parts.

Also, the FU-U Series has not only high-flex properties but a bending radius of 2 mm, which makes routing easy.

The cable can also be freely cut, which improves its ease of use.

We recommend this fibre for use with moving parts and in locations where space is limited.

*FU-48U, FU-49U, FU-58U, FU-59U, FU-69U, FU-70TU, FU-70U, FU79U

Thanks to its application of nylon fibre, a new material, this sensor has achieved a service life that is approximately 50 times that of conventional products.

The improved strength of the coating has reduced the force that is applied to the internal fibre cores.

Detections from moving parts such as robot arms

Space-saving installation that fits different shapes

| Angle | 90° to the left and right |

|---|---|

| Bend radius | R = 30 mm |

| Weight | W = 20 g |

| Speed | 30 times/minute (1 time indicates a round trip from left to right) |

| Test body | FU-U Series fibre |

*FU-48U, FU-49U, FU-58U, FU-59U, FU-69U, FU-70TU, FU-70U, FU79U

This fibre can be installed in any shape without having to worry about the fibre breaking due to bends.

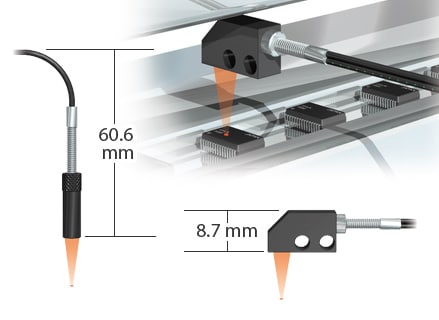

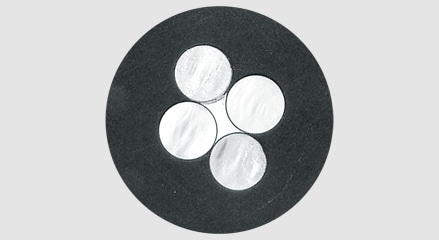

Conventional high-flex fibre

Four fibre cores were used. This fibre had a bend radius of 4 mm.

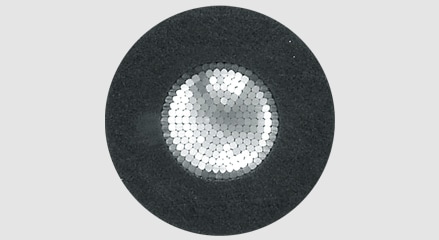

New high-flex fibre

A multi-core fibee is used. This fibre has achieved a bend radius of 2 mm.

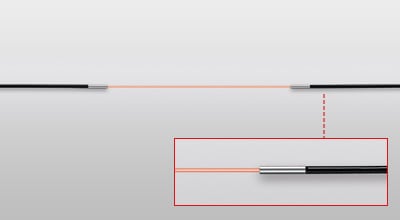

This fibre cable can be cut freely and has achieved a diameter of 1 mm.

Even though this is an ultra superfine type, it has achieved a long distance of 590 mm (in MEGA mode).

It also bends easily, with a bend radius of 2 mm, which makes it possible to install this sensor in a variety of spaces.

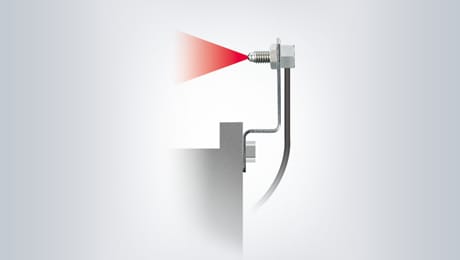

With this sensor, long-distance detections of 3500 mm (FU-70TU) are possible thanks to the built-in ball lens.

This sensor has high power, which makes it resilient to dirt, and has a structure that makes it difficult for light wraparound to occur because of the narrow aperture angle of approximately 24° achieved by the lens.

In addition, conventional sensors used lens units, and vibrations would cause these lens units to become loose and come free.

These sensors can even be used without worry in locations where high-flex properties are required and where vibrations occur.

The fluorocarbon resin coating of the oil/chemical-resistant types provides protection from the intrusion of liquids.

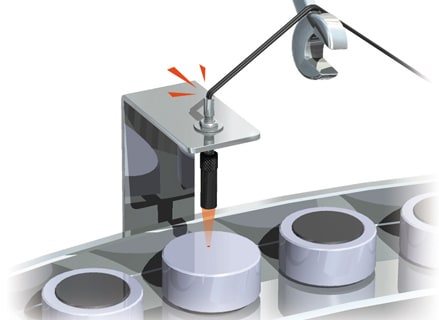

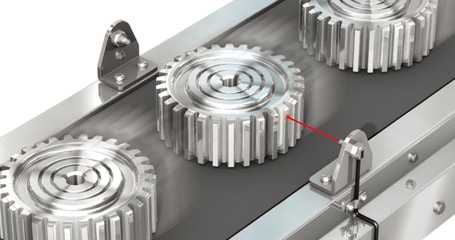

Detection of drill breakage in environments where coolant is used

Compared to other materials, coating sensors in fluorocarbon resin makes these sensors more resistant to a variety of chemicals.

: Good : Possible under certain conditions : Not possible

| Material | Chemical name | ||||||

|---|---|---|---|---|---|---|---|

| Acetone | Methylethyl ketone | Benzene | Methyl alcohol | Toluene | Hydrochloric acid | Sulphuric acid (98%) | |

| Fluorocarbon resin | |||||||

| ABS | |||||||

| Polycarbonate | |||||||

The FU-92, FU-96, FU-96T, and FU-98 all have built-in lenses.

The detecting distance is 3600 mm in FINE mode, which is the default mode. For workpieces that block the light, these sensors can obtain a large difference in light intensity between when workpieces are present and when they are not.

Therefore, it is difficult for these sensors to malfunction due to dirt or dust contamination.

FU-96T

The main unit's mounting holes make it possible to install the sensor as-is. The side-view shape makes it possible to install this sensor even in locations where space is limited.

FU-98

A dedicated mounting bracket (OP-87095, material: SUS316) is available. The main unit has protrusions, so the mounting bracket can be affixed to the main unit securely and without slippage.

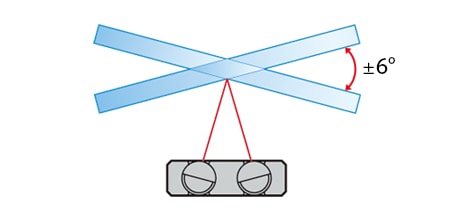

The transmitter and receiver are separated in an angled design.

This reduces malfunctions caused by liquid pooling, which is a problem with conventional reflective types.

Also, because the tips are curved surfaces, it is difficult for drops of water to pool on the detecting surface.

![An SUS type is also available. / [FU-97P] PVC securing bracket type / 9.6 mm thin type / [FU-97S] SUS316L securing bracket type](/Images/oil_chemical-resistant_img_07_1997581.jpg)

Small diameter refers to our fibre units that have narrow optical axis diameters. Narrow optical axis diameters are useful in detecting microscopic workpieces.

These sensors are suited to applications such as insertion confirmation and bend detection of fine-pitch connector pins, minuscule chip detection, and workpiece positioning.

The optical axis diameter and the core fibre diameter (lens diameter) are the same.

The aperture angle indicates the amount that the light spreads in relation to the optical axis.

FU-51TZ

FU-53TZ

FU-57TZ

The flat bracket types can be installed directly.

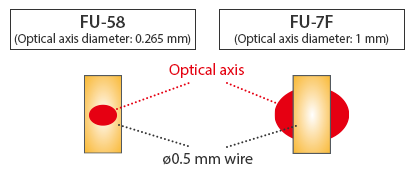

(Example) Detecting a ø0.5 mm wire

The FU-58 (ø0.265 mm) completely blocks the optical axis.

The FU-7F (ø1 mm) only blocks half of the optical axis.

The fibre that has an optical axis diameter narrower than the workpiece makes it easier to obtain the sensitivity difference!

FU-58U

FU-59U

FU-79U

These sensors have both bend resistance, with a bend radius of 2 mm, and high-flex properties, with the capability of being bent 50 million times. We recommend the use of these sensors in locations where cable routing is difficult and with moving parts such as transfer chucks.

FU-75F

*The sleeve cannot be bent.

The sleeve is narrow, with a diameter of 0.82 mm, and has a length of 15 mm.

Even in locations with limited space, such as locations where the passage of microscopic electronic components is checked, these sensors can be installed so long as there is enough of a gap through which to pass the sleeve.

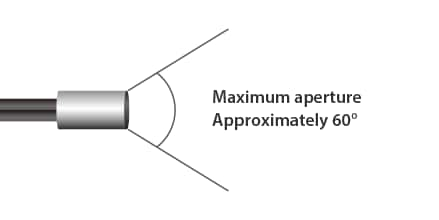

The standard fibre unit aperture angle is approximately 60°.

In cases where sensors have to be installed in a narrow space or where light wraparound is expected to occur, we recommend focused-beam fibre units, which have narrow aperture angles.

FU-18M

The integrated reflector, which bends the optical axis by 90°, and condenser lens, which narrows the aperture angle, improve the stability of the projected light.

Separate construction

Integrated construction (FU-18M)

Because the FU-18M has a prismatic case, optical-axis alignment only needs to be performed in directions perpendicular to the optical axis.

FU-16/16Z

FU-50

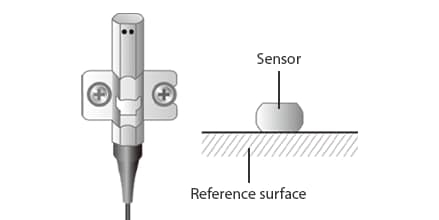

Position the fibre unit so that the side with the carved seal faces up and the side without the carved seal is the reference surface.

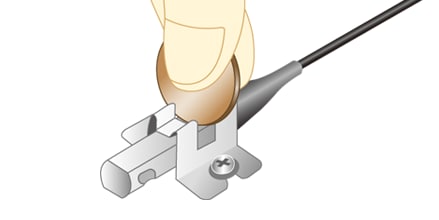

Insert a coin or similar object into the groove of the mounting bracket. Twist this object to the left and right to align the optical axis.

F-4

F-5

FU-96T

Focused-beam fibre units reduce light spreading by way of their lenses, which also makes it possible for these units to reduce the effect of stray lights.

The smaller the aperture angle, the more stray lights can be prevented. Preventing stray lights is effective in detections such as those shown below.

Incorrect detection caused by stray lights

Even though the workpiece blocks the optical axis, the stray lights leads to an incorrect detection.

If the aperture angle is small...

The effect of stray lights is eliminated!

FU-40S

Detecting distance

MEGA: 15 to 70 mm, FINE: 15 to 30 mm

These are lenses that are made from curved surfaces, not from spheres or planes.

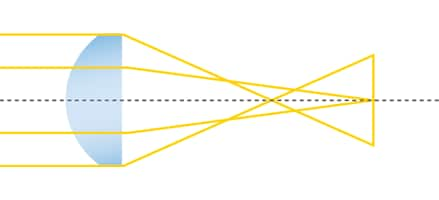

The largest characteristic of these lenses is their small aberration, which is generated by spherical lenses (which means, aspherical lenses receive light efficiently.) Even if the lens aperture is made larger in order to increase the amount of light that is handled, the aberration becomes small.

Spherical lens

The focal points are misaligned; aberration is present.

Aspherical lens

The focal points are aligned; no aberration is present.

Aberration means that the focal points of the light that enters from the centre of the lens and of the light that enters from the edges of the lens are misaligned. This is useful in detections of black, lustrous, and transparent workpieces at long distances.

FU-38L

Detecting distance

MEGA: 8 to 38 mm, FINE: 8 to 32 mm

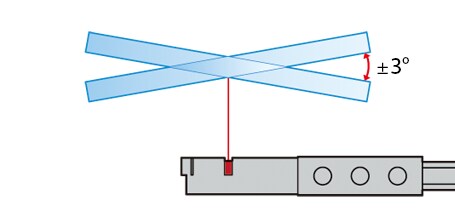

Thanks to KEYENCE’s proprietary optical design, it is difficult for this sensor to be affected by the tilting of workpieces.

Horizontal direction

Vertical direction

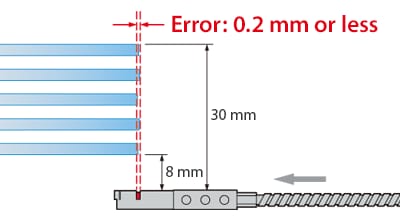

This sensor has achieved a positioning accuracy of 0.2 mm or less at a distance of 8 to 30 mm.*

*Data from detections of glass substrate (investigation performed by KEYENCE)

Past definite-reflective (image)

FU-38L (image)

Narrowing the aperture width to limit the field of vision

FU-38S

Detecting distance

MEGA: 0 to 25 mm, FINE: 0 to 25 mm

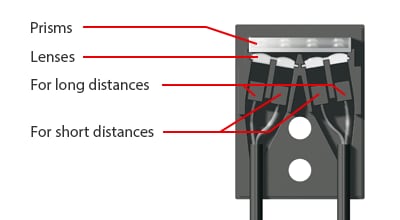

Two pairs of transmitters and receivers are installed within the sensor.

One set is used for long distances and the other for short distances.

This structure makes it possible for this sensor to perform detections at distances ranging from 0 mm all the way up to a long distance of 25 mm. Even if there are variations in the distance from the sensor to the workpiece, stable detections can be performed.

Transmitters and receivers are installed on the outside (for long distances) and on the inside (for short distances).

The structure in which light is reflected by the prisms makes it possible to achieve the thin design.

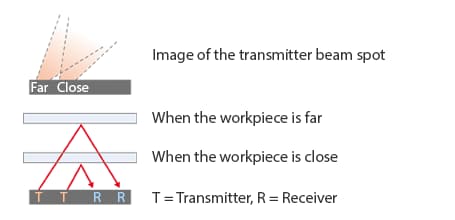

Images of the transmitter beam spot and detection

Images of detection when the workpiece is tilted

The transmitter and receiver for long distances are used to support the case when there is a long distance to the workpiece, and the transmitter and receiver for short distances are used to support the case when there is a short distance to the workpiece.

FU-95S

Even if there are bubbles, it's OK.

Because detection is performed with a series of 16 optical axes, even if some of the optical axes are affected by factors such as bubbles and drops of water, detection can still be performed with the remaining optical axes.

This sensor can be mounted on a tube with a diameter of 4 to 26 mm. The bend radius of the free-cut fibre is R5, which improves routing freedom.

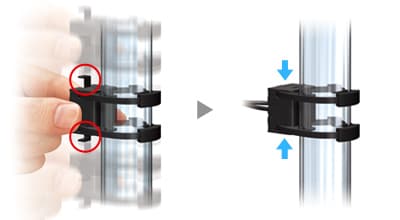

Position adjustment Easy locking

The scale has a width of 12 mm, which makes it easy to check the desired detection position. In addition, it is possible to perform detections at an arbitrary position within the range of the scale by making minute adjustments to the sensitivity.

FU-95W

For use with tubes that have a diameter of 26 mm or more

The bend radius of the free-cut fibre is R5, which makes routing easy.

[OP-82177, dedicated option for the FU-95W; sold separately] Cable tie × 2,

nonslip rubber × 2 Tube diameters from 26 to 80 mm are supported.

When there is no liquid in the tube, the difference between the refractive indexes of the tube and of air is large, so light is reflected by the inside of the tube and returns to the receiver.

In contrast, when liquid is present, the difference between the refractive indexes of the tube and of the liquid is small, so the majority of the light is radiated into the liquid and does not return to the receiver.

This characteristic is used to detect the presence of liquid.

No liquid present

Liquid present

Bubbles present

FU-93Z / FU-93

| Model | Heat resistant temperature | Fluorocarbon resin | Fibre part |

|---|---|---|---|

| FU-93Z | -40 to +50°C | R40* | R0.5 |

| FU-93 | -40 to +70°C | R25 |

*The fibre cannot be bent for a length of 80 mm from its tip.

When the tip is in air, the difference between the refractive indexes of the fluorocarbon resin and of air is large, so all the light is reflected back in the direction from whence it came (to the receiver).

In contrast, the difference between the refractive indexes of the fluorocarbon resin in liquid and of the liquid itself is small, so the majority of the light is radiated into the liquid and does not return to the receiver.

This characteristic is used to detect the presence of liquid.