Shot Blasting Observation and Measurement Using Digital Microscopes

Shot blasting is a processing method in which pieces of media (small pieces of sand or small steel or cast iron balls) are sprayed at high speed at a workpiece, shaving down the workpiece’s surface by creating small projections and depressions on it. Polishing results in a smooth surface finish, but shot blasting results in a rough surface. This section provides an overview of shot blasting and introduces examples of its observation and measurement using a digital microscope.

- What Is Shot Blasting?

- Workpiece and Media Materials

- Purposes and Effects of Shot Blasting

- Shot Blasting Observation and Measurement Examples Using a Digital Microscope

What Is Shot Blasting?

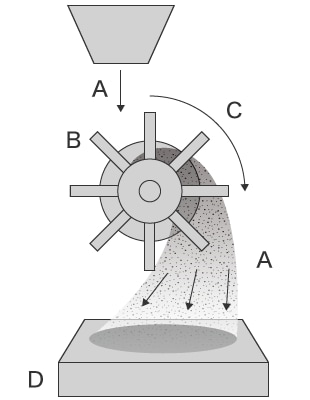

This process is called shot blasting because small steel or cast iron balls (shot) are sprayed at Shot blasting is a process where small steel or cast iron balls (shots) are rapidly sprayed (blasting) using a rotating impeller. These balls are propelled at high speed onto the blade, applying the media through centrifugal force. In comparison, the method in which the media is sprayed by compressed air is called air blasting or sandblasting.

Shot blasting

A motor causes the impeller to rotate, spraying the media by centrifugal force. Because no compressor is necessary, this method has lower energy and cost requirements. However, the processing force is not easy to adjust, making it difficult to obtain highly accurate processing.

Air blasting (sandblasting)

The media is sprayed by the compressed air from the compressor. Because the pressure can be adjusted easily, this method provides highly accurate processing.

Workpiece and Media Materials

This section introduces the main workpiece and media materials.

- Workpieces

- Metal, ceramic, plastic, glass, and rubber

- Media

- Small steel or cast iron balls (shot), sand, stainless steel, alumina, copper, glass, resin, plastic, and walnut powder

Purposes and Effects of Shot Blasting

- Rust and dirt removal

- Rust removal from metal surfaces, sand removal from die cast parts, welding spatter removal, and coating/oil stain removal

- Burr removal

- Burr removal after pressing or machining

- Creating projections and depressions

- This process improves the adhesion of coating, plating, bonding, etc.

Satin processing provides reflection prevention as well as improving oil reception, friction force, and heat dissipation.

- Shot peening

- Compressive residual stress improves the wear resistance, chipping resistance, and fatigue strength.

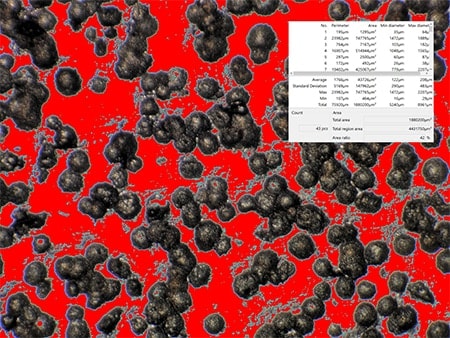

Shot Blasting Observation and Measurement Examples Using a Digital Microscope

These are the latest examples of shot blasting observation and measurement using KEYENCE’s VHX Series 4K Digital Microscope.