Shape / Profile

When selecting a sensor for 2D measurements, the first step is to choose a method for generating a profile of the target. This can be performed by scanning a 1D sensor over a surface, using a laser line, or working from a 3D image. The target material, shape, and size will all play a role in determining the best fit. Check out some typical methods below, or request a free consultation with a measurement expert.

Profile tire treads and sidewalls with multiple 2D laser profilers.

2D/3D Laser Profiler

LJ-X8000 series

Inspect for lamination misalignment after winding. With a minimum X-resolution of 2.5 μm, the LJ-X8000 Series accurately measures the profile of each electrode.

2D/3D Laser Profiler

LJ-X8000 series

Provide feedback about disconnected locations in electrodes before lamination. Accurately acquire the profile of electrode terminals to perform high-accuracy inspection of edge locations.

2D/3D Laser Profiler

LJ-X8000 series

Measure the profile of a wafer edge. By selecting one of the inspection tools such as Height Difference/Width or Angle, users can start measurement easily. The high-resolution image capturing using 3200 points/profile achieves highly accurate profile measurement that was impossible with conventional methods.

2D/3D Laser Profiler

LJ-X8000 series

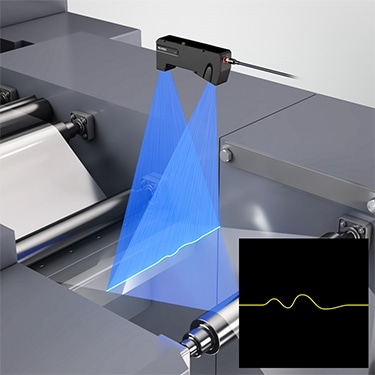

Film curvature and wrinkling measurements are performed using a blue laser with a maximum width of 720 mm. Measurement is possible even for transparent targets thanks to the wide dynamic range of the CMOS sensor.

2D/3D Laser Profiler

LJ-X8000 series