Case Studies Customer Testimonials — Measuring Radius (R) / Inner Diameter (ID)

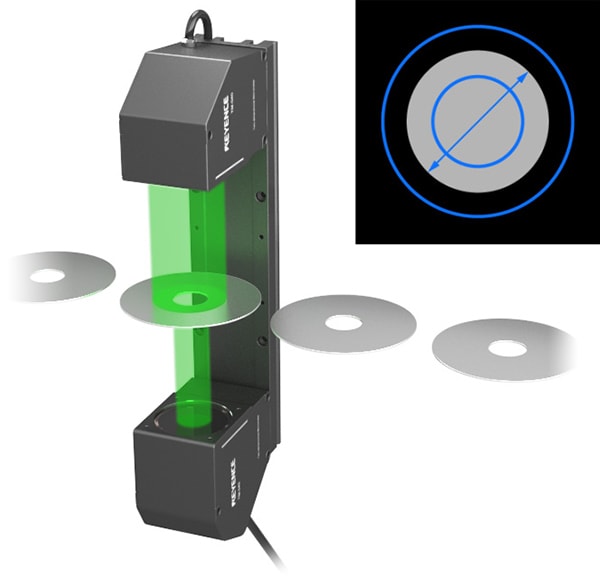

Case: 1 Inner Diameter Measurement of Disks

| Industry | Electronic and Electrical Industry |

|---|---|

| Application | Inner Diameter Measurement of Disks |

| Model Adopted | TM-3000 Series |

We used a 1D micrometer to scan the target and considered the maximum value to be the inner diameter.

With its 2D optical projection method, the TM Series Optical Micrometer has achieved the inner diameter inspection without scanning.

Customer

CustomerTestimonial

Thank you for using KEYENCE products.

We know that inner diameter measurement is one of the most difficult dimensions to measure. Since the target of this case had a donut shape, we could measure the inner diameter easily by projecting a cylindrical light, eliminating the need of moving the target.

KEYENCE

KEYENCE

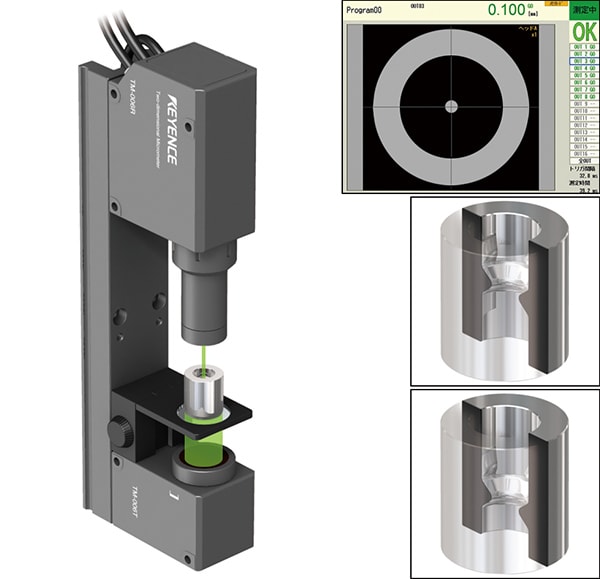

Case: 2 Inner Diameter Measurement of Dies

| Industry | Transport/Metals Industry |

|---|---|

| Application | Inner Diameter Measurement of Dies |

| Model Adopted | TM-3000 Series |

Our previous regular maintenance did not measure the die hole directly but measured the weight of the wire material passed through the hole. Such indirect measurement produced significant errors and required a lot of time and effort.

The TM Series we purchased can accurately measure a hole diameter with less error than a micrometer.

Customer

CustomerTestimonial

Thank you for using KEYENCE products.

At first, the customer said they wanted to measure the outer diameter of wire materials. When we found out that they actually wanted to measure the inner diameter of a die, so we introduced the TM Series. We are glad to hear that the customer was satisfied with our product.

KEYENCE

KEYENCE