Line Scan Camera

Line Scan series

Line Scan Camera Line Scan series

Complete Line Scan Camera Solution

All the experience with area cameras can now be used with line scan cameras.

- Easy camera setup

- The most powerful and advanced hardware in the image processing market

- LumiTraxTM specular reflection mode

High-speed cameras for inspection and defect analysis on large parts, continuous webs, and cylinders.

Applications

-

Inspection of pinholes and dirt on a sheet

-

Visual inspection of a bearing

-

Appearance inspection of sanitary products

-

Visual inspection after printing electrodes

Features

The Same Ease-of-Use of Area Cameras Is Available with a Line Scan Camera System

The controller with interchangeable camera modules makes it easy to incorporate a line scan inspection system that traditionally could only be done with complex, specialised machinery.

Hardware tough enough to handle continuous long-term operation

Built-in firmware eliminates issues with PC-based solutions.

Easy Camera Setup

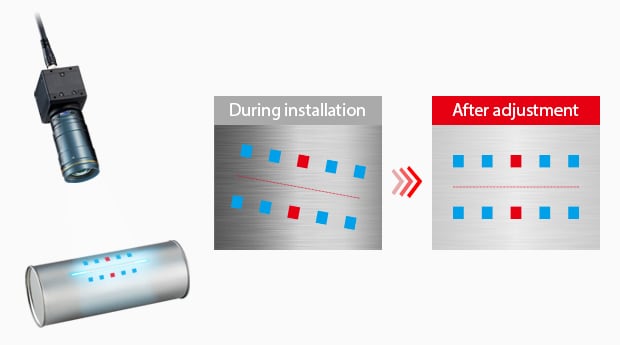

The camera equipped with an "LED Pointer" allows the line camera to instantly find the position of the image it is capturing and find the optimal installation conditions in the shortest possible time.

In addition, the angle sensors mounted on the camera and lighting (*only for some models) not only find the optimal installation conditions in the shortest time possible, but also detect installation deviations during operation.

Line scan camera with LED Pointer

Cameras come equipped with LED Pointers. These pointers make it possible to instantly identify the location being imaged when the camera is installed.

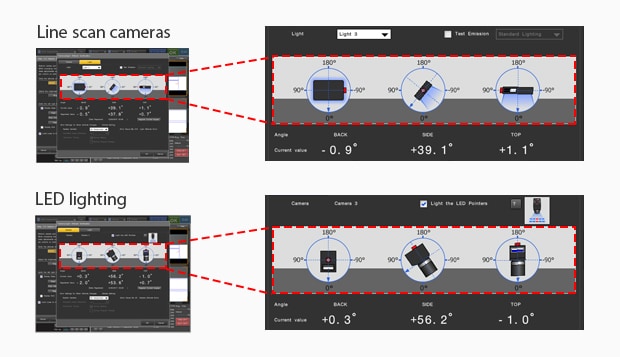

Line scan camera settings navigator

Sensors are installed in the camera and lighting in order to digitally control the position of each. This reduces the time needed for previously time-consuming optical axis alignment.

Image Optimisation Algorithms for Stable Appearance Inspection

Visual inspection tools with a variety of parameters and visualisation enable defect extraction according to your needs.

The defect classification function automatically classifies scratches and foreign objects detected by the inspection tool according to specified conditions.

Mapping display and saving of cut-out images are also available.

Unique image processing algorithms to extract the toughest features

- Robust preprocessing filters eliminate problem factors.

- Expanded custom filters satisfy every need.

Robust defect detection and analysis

- Appearance inspection tools allow the use of various parameters and visualisation.

- Defect extraction tools to meet any need.

- Target classification function helps organise data and maintain proper inspection.